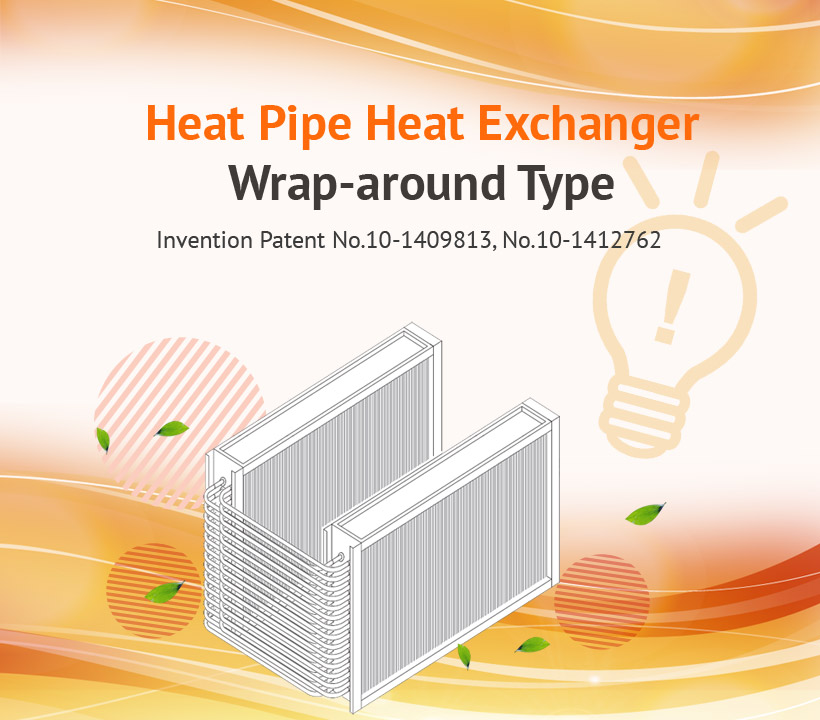

WRAP-AROUND HEAT PIPE HEAT EXCHANGER

Our's wrap-around heat pipe heat exchangers can reduce

operating costs and cooler capacity when coupled with

fresh air handling unit, air conditioning system of large

amount latent heat, constant temperature and humidity

control system and dehumidifying system.

In addition, it can extend the life of air blowing system

with reduction of relative humidity to, as it prevents

duct corrosion.

operating costs and cooler capacity when coupled with

fresh air handling unit, air conditioning system of large

amount latent heat, constant temperature and humidity

control system and dehumidifying system.

In addition, it can extend the life of air blowing system

with reduction of relative humidity to, as it prevents

duct corrosion.

STRUCTURE AND OPERATING PRINCIPLE

The wrap-around heat exchanger : heat pipe is installed around the cooling coil for the best dehumidifying performance.

Evaporator section of heat pipe installed on the front side of cooling coil precooling for entering air of cooling coil, enhanced performance of dehumidification by pre-cooling to entering air of cooling coil, the condenser section of heat pipe installed on the rear side of cooling coil reheating for leaving air of cooling coil as pre-cooling in the evaporator section of heat pipe installed on the front side cooling coil and decreased relative humidity of supply air.

Our's wrap-around heat pipe heat exchanger starts working when occurred temperature difference between inlet and outlet of air passing through the cooling coil.

Without using any electric power, the heat from entering air is transferred to the other low temperature air system which has passed through the cooling coil, hence saves a large amount of energy.

Evaporator section of heat pipe installed on the front side of cooling coil precooling for entering air of cooling coil, enhanced performance of dehumidification by pre-cooling to entering air of cooling coil, the condenser section of heat pipe installed on the rear side of cooling coil reheating for leaving air of cooling coil as pre-cooling in the evaporator section of heat pipe installed on the front side cooling coil and decreased relative humidity of supply air.

Our's wrap-around heat pipe heat exchanger starts working when occurred temperature difference between inlet and outlet of air passing through the cooling coil.

Without using any electric power, the heat from entering air is transferred to the other low temperature air system which has passed through the cooling coil, hence saves a large amount of energy.